Laminar / Ionic Industries MOU

Ionic Industries is pleased to report it has signed an MOU with Korean manufacturer Laminar for the development of graphene and graphene oxide (GO) production technologies.

Laminar is the world’s only-manufacturer of Taylor flow reactors which deliver unsurpassed capabilities with more efficient and higher quality chemical reactions and improved industrial processing performance. Laminar clients understand the benefits of Taylor flow reactors in in production of finely engineered chemicals and materials. Its clients include some of the world’s largest companies: LG, Tanaka Chemicals, Nippon Mining and Metals, Sumitomo Chemicals and educational institutes such as MIT and Argonne National Laboratory.

Laminar CEO, Mr Jongpal Hong contacted Ionic Industries’ lead researcher at Monash University, Associate Professor Mainak Majumder for his expertise in the field of graphene and graphene oxide production. Through several discussions and visits, the companies recognised a broad range of mutual benefits that could be obtained through cooperation and collaboration. A/Professor Majumder’s deep understanding and expertise will be combined with Laminar’s equipment to deliver unparalleled capabilities in the production of high-value graphene and graphene oxide, tapping into rapidly growing demand for these products. Laminar is the world’s only-manufacturer of Taylor flow reactors which deliver unsurpassed capabilities with more efficient and higher quality chemical reactions and improved industrial processing performance. Laminar clients understand the benefits of Taylor flow reactors in in production of finely engineered chemicals and materials. Its clients include some of the world’s largest companies: LG, Tanaka Chemicals, Nippon Mining and Metals, Sumitomo Chemicals and educational institutes such as MIT and Argonne National Laboratory.

Laminar and Ionic have identified areas of common interest for cooperation including:

- Exchange of information about graphene and graphene oxide materials;

- Exchange of information about methods of manufacturing, handling and applying graphene and graphene oxide materials;

- Identifying further areas for collaboration around the scientific and engineering disciplines associated with graphene and graphene oxide manufacturing;

- Identification of commercialization opportunities, including markets, customers and commercial partnerships;

- Development and protection of intellectual property in the field of graphene and graphene oxide production;

- Opportunities around government programs that may be used to accelerate research and development.

The Companies will plan to work together in the following ways:

- Exchanges of information;

- Participation in workshops and group discussions;

- Joint presentations at commercial events such as conferences, workshops or potential partnership opportunities;

- Visits by representatives to each other’s facilities;

- Demonstrations of technologies and processes relevant to graphene and graphene oxide production;

- Application for joint government funding programs; and

- Other forms of cooperation as may arise.

This MOU is the first step in establishing a relationship with Laminar that may lead to Ionic’s first revenues through licencing of its intellectual property. Ionic Industries’ Managing Director, Simon Savage expressed his enthusiasm for the collaboration:

This is an exciting step for Ionic as it represents collaboration with a dynamic, progressive manufacturer that is well-aligned with Ionic’s goals and objectives as a technology platform built around our expertise in graphene and graphene oxide materials. This relationship demonstrates a very clear path to tangible, near-term commercial outcomes for Ionic.

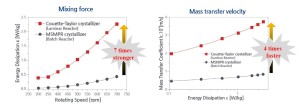

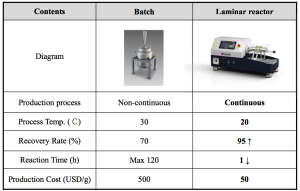

Taylor flow reactors uniquely combines the advantage of a plug-flow reactor with micro-mixing capabilities which are known to improve reaction kinetics, reduce chemical consumption, improve product homogeneity and increase process safety. The Laminar reactor is ideal for processing graphene and graphene oxide using Ionic’s processes to reduce the time required, increase the controllability of a continuous flow process design compared to batch reactor. Laminar has also developed a semi-continuous process to produce graphene oxide utilizing their reactor which represents a significant step toward commercialisation and provides Ionic the confidence to work on further improvements to the process and upscaling the production of GO.

The advantages of Laminar’s proprietary reactor technology are illustrated below:

The commercial opportunity for Ionic lies in potential licensing arrangements or joint ventures to produce graphene and GO products by combining Ionic’s proprietary processes with Laminar’s IP, equipment and manufacturing know-how. Laminar’s existing market access and client base will serve as the initial target market for these products.

Laminar will also gain considerably from partnering with Ionic. Firstly, they will have access to significant data that Monash has developed around GO production which will be very useful in targeting other manufacturing processes like Laminar’s existing oxidation process. The modelling insights will enable Laminar to modify or improve the design of its reactor; whilst scale-up studies will enable them to venture into larger and new product markets. Additionally, the critical evaluation of Laminar’s technology in demanding applications such as in the oxidation reactions would enhance their credibility and create new customer base for their innovative reactor.

This agreement represents another success for the collaboration between Ionic Industries and Monash University, specifically with A/Professor Majumder and his team. With this MOU, the relationship between A/Professor Majumder and Ionic is further strengthened on the back of recent collaboration with Clean TeQ and ongoing work on Ionic’s micro-supercapacitor program.

This partnership represents significant progress in Ionic’s strategy of commercialising graphene technologies through partnerships with industry-leading companies. The progress marks an important milestone in the company’s plans to raise further capital to commercialise these technologies along with other developments in water treatment and graphene planar super-capacitors.